However, the overall efficiency, flexibility and economy of InvoMilling clearly favor this process for gear production in smaller batches. When gear-cutting cycle times are compared between hobbing and InvoMilling, hobbing is sometimes faster, depending on the size of the gear and number of teeth. If you have InvoMilling, three tools will cover you from DP2 to 12, so much less tool inventory is required-that’s revolutionary.” “You have to place an order when you don’t have the right tool. Even with a huge inventory, it still may not be enough,” Nicklas Bylund, InvoMilling project leader at Sandvik, says. There’s one hob or gasher for each diametrical pitch size of gear. “A gear manufacturer usually has a large inventory of dedicated tools.

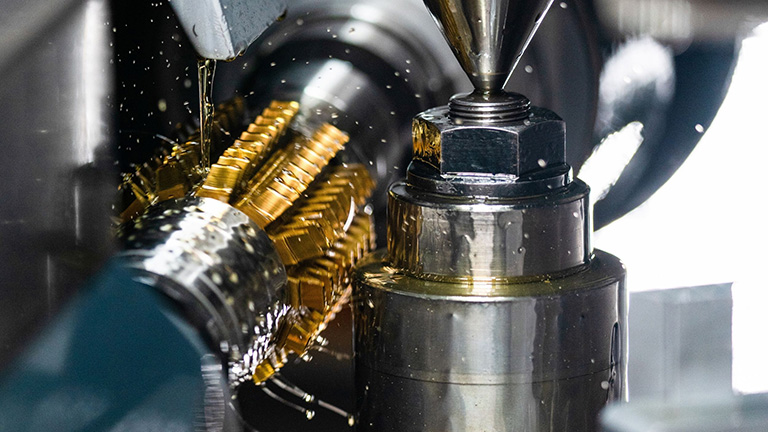

Gears with any helix angle-both involute and noninvolute profiles-can be produced with the same tools.Įliminating the need to stock individual hobbing tools, which are costly and involve a long leadtime to acquire various gear sizes, is one of the important advantages of this process. Sandvik Coromant has developed three disk cutter sizes (CoroMill 161, CoroMill 162 size 4 and CoroMill 162 size 6) to cover the range from module 2 to 12 or 12 to 2 DP (diametral pitch). Simply changing the tool path results in unlimited gear shapes producible with the same cutter. Simultaneous motion of the X and B axes or with the Y and B axes enables the milling cutter to follow an involute path. It is a combination of slot milling and multi-axis turn-milling. The name InvoMilling represents a new concept in involute milling that is an alternative to the specialized hobbing process. Likewise, general machining companies and job shops can add enhanced gear cutting to their range of machining operations, expanding the types of parts and part features they can handle. Shops that specialize in gear production can extend their services to customers requiring small batches of high-quality gears, or even single prototypes, at a very attractive price. This is a huge benefit to two classes of potential users. This capability makes the five-axis multitasking machine the ultimate in flexible gear cutting technology. No additional cost or added time to change from one profile to another is involved. Because a tool path can be reprogrammed quickly, the same cutter can produce an unlimited number of gear profiles within a certain, but rather wide, range. By virtue of new programming software, the tool path, not the shape of the cutter, determines the gear profile. This process enables a five-axis multitasking machine to produce gear-tooth geometry with off-the-shelf tooling.

InvoMilling is the name of a proprietary gear milling process developed by cutting tool manufacturer Sandvik Coromant with the cooperation of machine tool builder DMG/Mori Seiki.

0 kommentar(er)

0 kommentar(er)